Maintaining your compressed air equipment properly can help reduce your cost. If your equipment is not maintained properly, you may end up paying more than necessary. Fortunately, there are a number of things you can do to lower your costs. There are many ways to lower your compressed air costs, whether you’re a small business owner or a corporate executive. Manufacturer of Air Hoses Manufacturers of compressed air hoses will offer a variety of options including custom-made hoses that can be tailored to your needs. For applications that require flexible, oil-resistant hoses that resist weathering or aging, custom-made hoses can be…

Maintaining your compressed air equipment properly can help reduce your cost. If your equipment is not maintained properly, you may end up paying more than necessary. Fortunately, there are a number of things you can do to lower your costs. There are many ways to lower your compressed air costs, whether you’re a small business owner or a corporate executive.

Manufacturer of Air Hoses

Manufacturers of compressed air hoses will offer a variety of options including custom-made hoses that can be tailored to your needs. For applications that require flexible, oil-resistant hoses that resist weathering or aging, custom-made hoses can be used. High-quality compressed air hoses can withstand high pressure while remaining flexible and smooth.

The internal diameter (ID) of air hoses is a primary factor in choosing the correct size for your air hose. The more air you can carry, the larger your ID. Therefore, you should consider the size of your air tools and where you will install the hose to determine the size that will work best for you. Standard size for air hoses is 3/8″, or 1/2″. A metric size is 8mm, or 10mm.

The material used to manufacture a compressed air hose is also an important factor. Polyurethane hoses are lightweight and flexible but will not degrade under extreme temperatures. Nylon hoses are stronger than PU and can withstand higher pressure. This makes them an excellent choice for industrial applications.

Air Hose Fittings

Air hose fittings are available in different sizes and types. A fitting of this size is approximately quarter-inch in diameter. Some pneumatic tools may require different sizes. Depending on the fitting, the thread sizes can also vary. The best way to distinguish the different types is to use color-coding.

There are two types of air hose fittings available: manual and automated. Manual fittings require that the user inserts the hose and pulls it out. Automatic couplings are quick and simple to connect. The latter is ideal for busy workspaces as it eliminates the need for shut-off valves.

For personal or commercial use, a 3/8-inch fitting is commonly used with air compressors. These fittings are known for their efficiency and utility.

High Pressure Gas Hose for Air Compressors

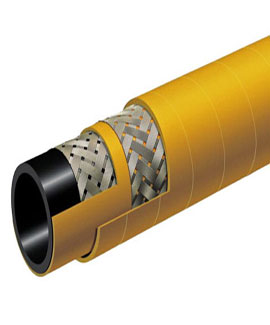

High pressures can be dangerous for compressors. High pressures require a special hose designed to handle the force. These hoses are typically made from flexible rubber hoses with wire reinforced sleeving, thick outer tubes, and wire-reinforced sleeves. They work well for most compressed air applications. They are also supplied with special fittings that prevent sudden fitting detachment. To reduce the risk of air leaking, they are often coated with an oil-based grease.

Rubber is one of the many materials that are available for high-pressure gas hoses for air compressors. Rubber is a cost-effective option for air hoses but it does have some drawbacks. Rubber is not flexible enough to withstand high pressure applications and can be damaged by gas. It is important to choose the right material for your application.