Wear-resistant rubber hoses are essential in various industries that require the transportation of abrasive materials such as cement, sand, and gravel. These hoses are also suitable for conveying materials like mining slurries and sludge. The unique design of these hoses makes them ideal for heavy-duty applications, and they are built to withstand high pressure and extreme temperatures.The most common type of wear-resistant rubber hose is made of natural rubber. Natural rubber is highly durable and resistant to wear and tear, making it an excellent choice for heavy-duty applications. Other materials that can be used to make wear-resistant hoses include synthetic…

Wear-resistant rubber hoses are essential in various industries that require the transportation of abrasive materials such as cement, sand, and gravel. These hoses are also suitable for conveying materials like mining slurries and sludge. The unique design of these hoses makes them ideal for heavy-duty applications, and they are built to withstand high pressure and extreme temperatures.The most common type of wear-resistant rubber hose is made of natural rubber. Natural rubber is highly durable and resistant to wear and tear, making it an excellent choice for heavy-duty applications. Other materials that can be used to make wear-resistant hoses include synthetic rubber, polyurethane, and UPE.Wear-resistant rubber hoses come in various sizes and lengths, allowing them to be customized to suit specific applications.

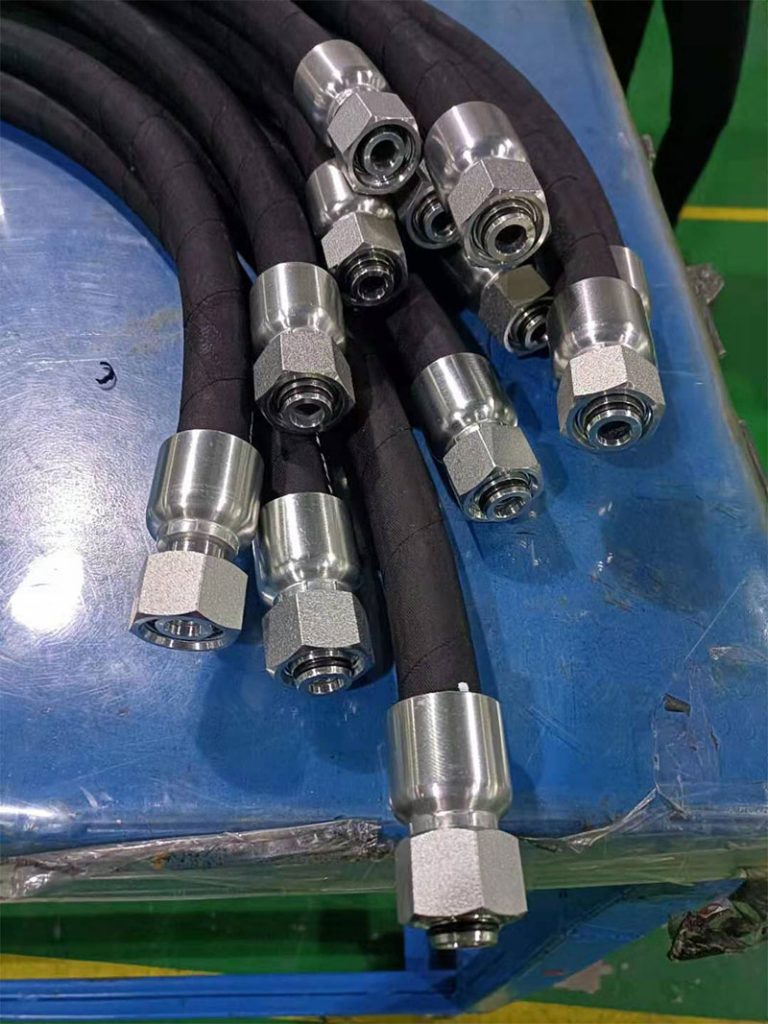

They are typically reinforced with steel wires, polyester fibers, or nylon cords to increase their strength and flexibility. The reinforcement also helps to prevent the hose from collapsing or rupturing under high pressure.One of the key features of wear-resistant rubber hoses is their ability to maintain their flexibility and performance even in harsh environments. They can withstand exposure to chemicals, oils, and other harsh substances, making them ideal for use in industrial settings. The hoses are also resistant to ozone and ultraviolet light, ensuring their longevity and reliability.Wear-resistant rubber hoses are commonly used in the mining industry to transport slurries, sand, and gravel. They are also used in the construction industry to transport cement and concrete. These hoses are highly versatile and can be used in a variety of applications, including agriculture, food processing, and chemical manufacturing.In addition to their durability and flexibility, wear-resistant rubber hoses are also easy to install and maintain. They can be connected to fittings and couplings, allowing for easy installation and removal. Regular maintenance is necessary to ensure their longevity and reliable performance. It is essential to inspect the hoses regularly for signs of wear and tear, such as cracks, abrasions, or bulges.Wear-resistant rubber hoses are essential in various industries that require the transportation of abrasive materials. They are built to withstand high pressure and extreme temperatures, making them ideal for heavy-duty applications. These hoses are highly versatile, easy to install, and maintain, ensuring their longevity and reliable performance.