High temperature and high pressure steam pipes are important industrial transportation pipelines, widely used in fields such as power generation, chemical, petrochemical, textile, etc. It can withstand steam transportation under high temperature and pressure, and has characteristics such as corrosion resistance, wear resistance, and pressure resistance. In this article, we will explore the structure, characteristics, and application fields of high-temperature and high-pressure steam pipes. High temperature and high pressure steam pipes are usually composed of three parts: inner rubber, reinforcement layer, and outer rubber. Among them, the inner rubber layer can resist chemical and physical corrosion, while the reinforcing layer…

High temperature and high pressure steam pipes are important industrial transportation pipelines, widely used in fields such as power generation, chemical, petrochemical, textile, etc. It can withstand steam transportation under high temperature and pressure, and has characteristics such as corrosion resistance, wear resistance, and pressure resistance. In this article, we will explore the structure, characteristics, and application fields of high-temperature and high-pressure steam pipes.

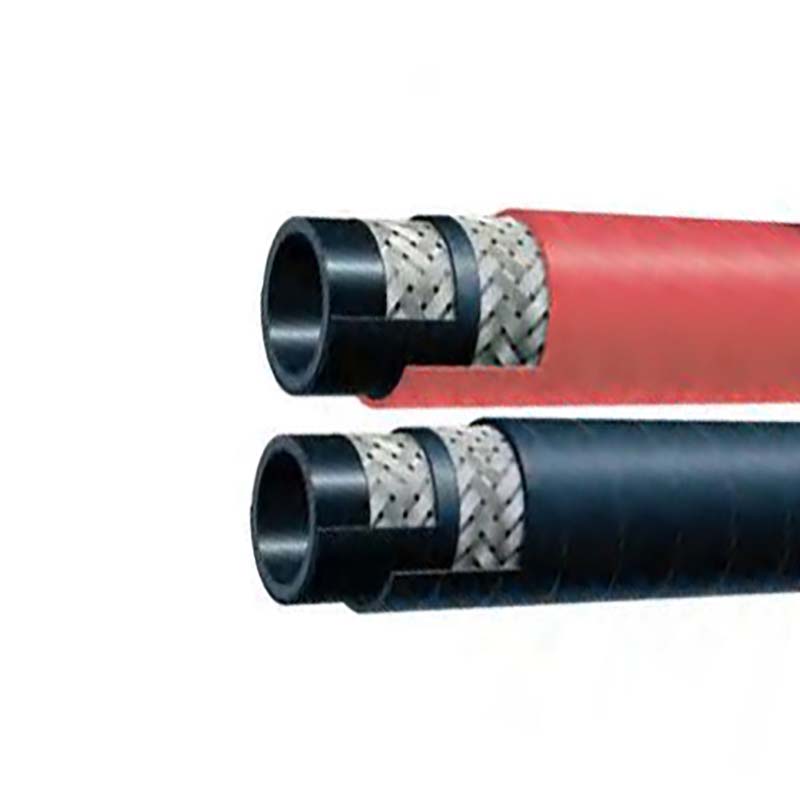

High temperature and high pressure steam pipes are usually composed of three parts: inner rubber, reinforcement layer, and outer rubber. Among them, the inner rubber layer can resist chemical and physical corrosion, while the reinforcing layer uses high-strength fiber materials such as polyester wire and glass fiber, which have excellent wear and pressure resistance. The outer rubber layer can prevent external corrosion and wear. This structure can effectively protect the internal steam and reduce leakage and loss.The characteristics of high-temperature and high-pressure steam pipes are also very obvious. Firstly, high-temperature and high-pressure steam pipes can withstand steam transportation under high temperature and pressure, meeting the transportation needs of the industrial field for high flow rate, high pressure, and high speed.

Secondly, high-temperature and high-pressure steam pipes are made of high-quality materials, which have good corrosion resistance, wear resistance, and pressure resistance, and can extend their service life. In addition, high-temperature and high-pressure steam pipes also have good sealing performance, which can effectively reduce steam leakage and energy loss.High temperature and high pressure steam pipes have a wide range of applications in industrial production. In the field of power generation, high-temperature and high-pressure steam pipes are used to transport steam and drive generator sets to generate electricity. In the field of chemical engineering, high-temperature and high-pressure steam pipes are used for heating and steam transportation in chemical production processes. In the field of petrochemical industry, high-temperature and high-pressure steam pipes are used for heating and steam transportation in refining and chemical production processes. In the textile industry, high-temperature and high-pressure steam pipes are used for heating and steam transportation in the textile production process.

Overall, high-temperature and high-pressure steam pipes, as an important industrial transportation pipeline, have wide application value in fields such as power generation, chemical industry, petrochemical industry, textile, etc. In the future, with the continuous progress of technology and the continuous development of industry, the application fields of high-temperature and high-pressure steam pipes will also continue to expand, and gradually develop towards more efficient, environmentally friendly, and safe directions

Inquiry

Please fill in your name and your message and do not forget mail and/or phone if you like to be contacted. We will reply in 24 hours.