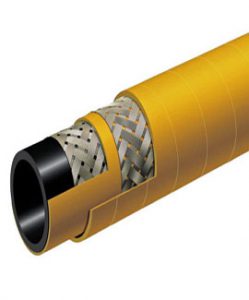

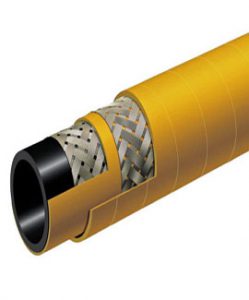

MT98 mining steel wire braided rubber hose is mainly used in the coal mining industry to transport mineral oil, water-based hydraulic oil or water. The inside of the pipe body is made of synthetic rubber with good oil resistance, and the outer layer is made of black oil-resistant oil. , Weather-resistant, wear-resistant synthetic rubber, this type of pipe can work in the environment of minus 40, but the maximum temperature cannot exceed 100 degrees Celsius; according to the different environmental requirements of customers, the middle layer is woven with one or more layers. High-strength steel wire for reinforcement. In order to better prevent and manage pneumonia caused by the new coronavirus, the Government Headquarters issued a notice to extend the 2020 Chinese New Year holiday to February 2, 2020. In order to reduce, prevent the spread of the disease and better protect the safety and health of workers and related personnel, the company will temporarily resume work on February 10, 2020 at the request of the government. During the holidays, letone will continue to provide business consulting and other services via email and mobile devices.

Hose has been involved in many industries, and the hoses used in different fields are different. Today we are going to talk about high-pressure oil drilling hoses. High-pressure oil drilling hoses have physiological inertness, UV resistance, ozone resistance, high and low temperature resistance (-80 to 300 degrees), high transparency, strong resilience, long-term compression resistance without deformation, oil resistance, stamping resistance, acid and alkali resistance, wear resistance, flame resistance, voltage resistance, electrical conductivity and other properties, which are not available in other types of pipes. LT301API 7K Series – Rotary Drilling and Vibration Damping Hose, which utilizes a highly robust, flexible, compact coiled hose construction, a very high ozone, weather and abrasion resistant hose sleeve, (the hose sleeve has a resistance to flammable (MSHA) and anti-static properties) as well as coupling solutions use the disadvantages, where crimp-style hose fittings create a strong, secure connection. The inner rubber layer is mostly imported materials, with extremely stable chemical properties and wear resistance. The multi-layer spiral steel wire is strengthened to meet the pressure requirements on the oil drilling platform, providing customers with the possibility of a variety of choices.

In 2017, we achieved the best half-year performance in the history of Litong: Super Hercules series products remain stable, 7K/16C products of oil drilling hoses have obtained API certification, newly developed Teflon high, medium and low pressure will be standard soft Tube. The name translated as “KING HOSE” in Chinese is “King of Hose”. The third phase of Litong was put into operation in 2019. The Xifa Compound Rubber Building of Litong Fluid Intelligent Industrial Park has been completed. The annual production capacity of GK190E is 10,000 tons. The automatic rubber compounding intelligent production line was put into operation smoothly. The company’s API oil cracking drilling hose product series has obtained the American Bureau of Shipping ABS (oil drilling and steel wire braided hose assembly), Lloyd’s fire certification and other products used in harsh environments such as high risk, high pressure and high temperature, which is enough to prove its reliability sex. Fully meet the needs of equipment in intelligent manufacturing, API oil drilling, mining and metallurgy, rail transit, energy, chemical and other fields. Help China’s 10-year high-end equipment manufacturing.